Description

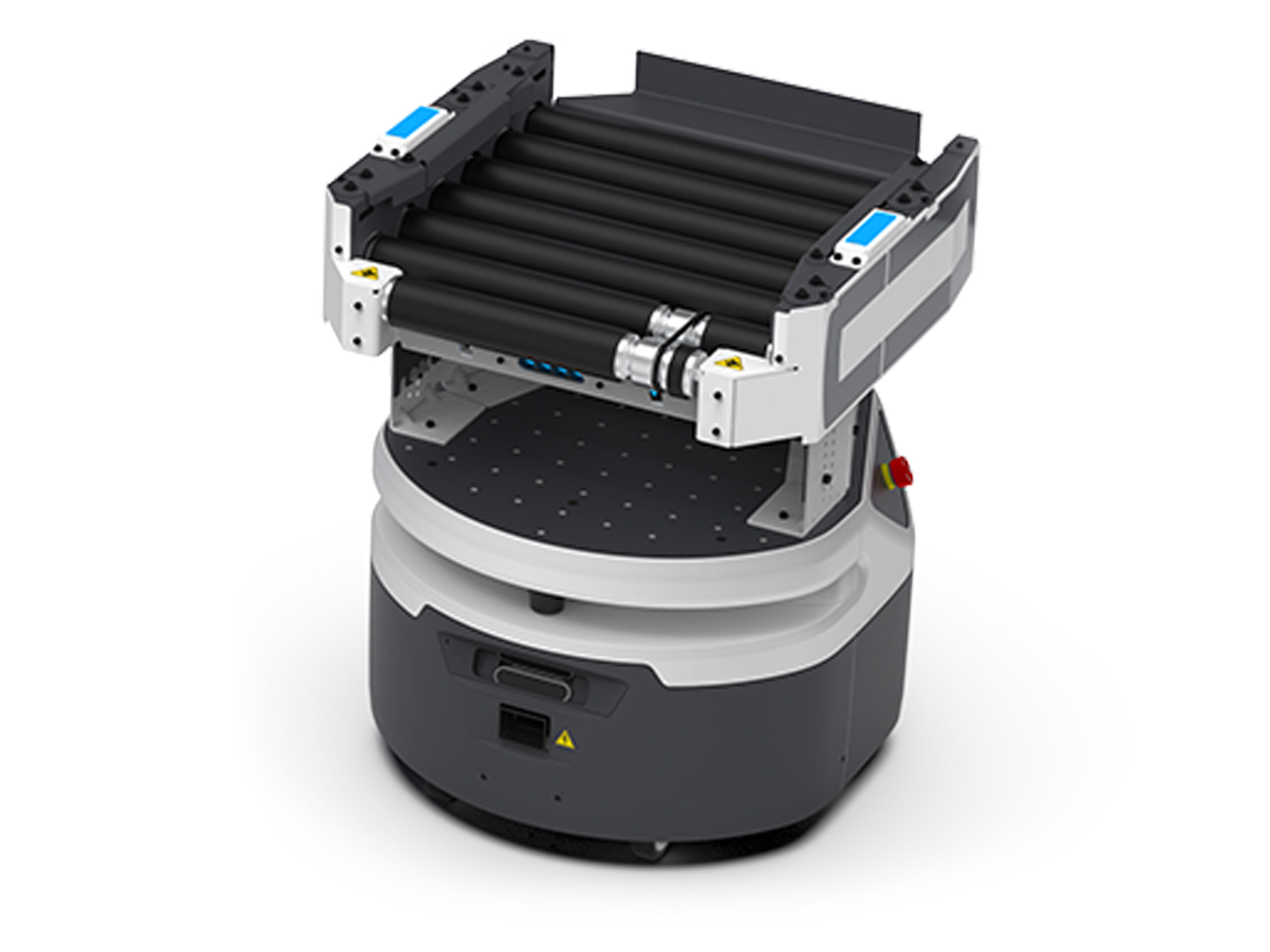

- Fixed infrastructure occupies valuable floor space and is both costly and time consuming to modify when changes arise. AMRs are a flexible alternative for operations looking to eliminate linear bottlenecks and reclaim floor space.

- To optimize production capacity, it is crucial to integrate key automated substations like CNC machines and AS/RS, despite their frequent isolation from each other.

- AMRs bridge the gap between stations by autonomously delivering work-in-progress materials.

- Supports lean manufacturing by autonomously transporting raw, WIP, and finished good materials to and from assembly lines or work cells, enabling your highly-skilled technicians to focus on value-added tasks instead of waiting for material.

Reviews

There are no reviews yet.