Description

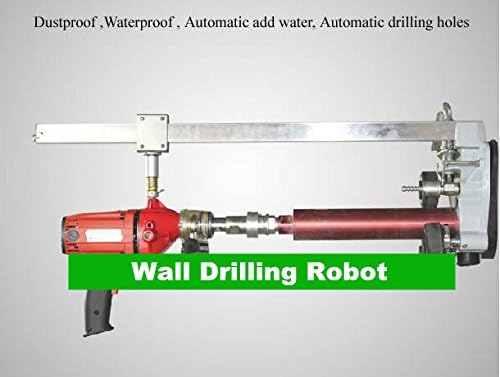

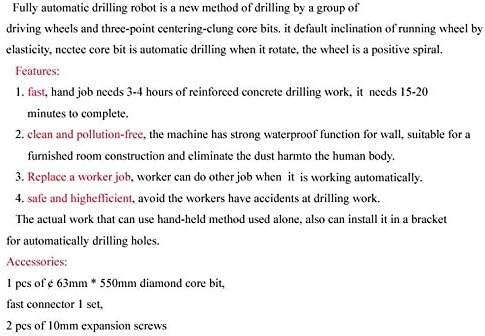

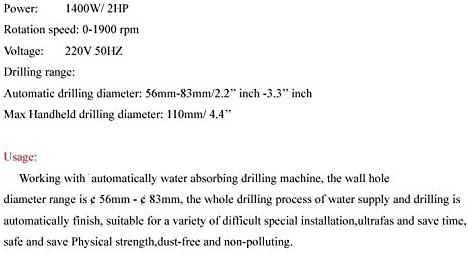

- GOWE Wall Drilling Robot Rated Voltage: 220V; Max. Drilling Diameter: 3.3” inch / 83mm; Frequency: 50hz; Application: Automatic drilling holes in the wall; No-Load Speed: 0-1900 rpm; Drill Type: Core Drill; Weight: 17KG; Rated Input Power: 1400W/2HP;

- Robot drilling is a type of automated machining operation where a drilling tool is fixed to the end of an industrial robot. Unlike conventional computer numerical controlled (CNC) drilling machines, robots have a larger workspace and can handle more complex shapes.

- One of the major benefits of using robot drilling systems is their flexibility. With conventional CNC drilling, you are usually restricted to drilling in one or maybe two planes. With robots, however, you can drill in almost any orientation that you like.

- You could only achieve this type of project with robot drilling. Manual drilling would be too labor-intensive and the accuracy would be inconsistent. Other forms of drilling automation just wouldn’t be able to drill from so many different orientations.

- Robots indeed have a lower stiffness than conventional CNC machines. Industrial robot arms often have a stiffness of just 1 Newton per micrometer. This means they can withstand 50 times less force than conventional machines.

- When you’re choosing a robot drilling system, you need to pay close attention to the material properties. With the right combination of robot and workpiece material, you can ensure that your robot drilling system has adequate stiffness for your chosen task.

- You should start by assessing the needs of your task and comparing the various robots on the market. You can use our Robot Library to narrow down robots with particular traits (such as repeatability and payload) but you will need to ask the manufacturer for details about stiffness.

- You can significantly speed up your programming by using a programming tool that incorporates point programming.

Reviews

There are no reviews yet.