Fanuc

-

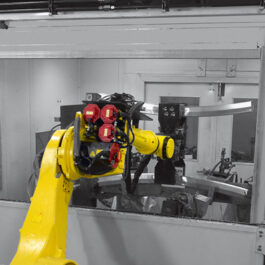

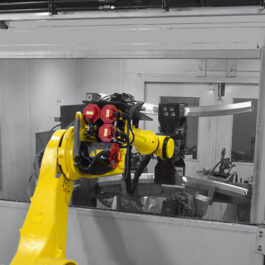

Arc Welding Robot ARC Mate 100iD/8L

- Ideally suited for working in compact robotic cells, the slimline ARC Mate 100iD/8L occupies a small footprint and can be installed upside down or angle mounted for even more flexibility.

-

Arc Welding Robot ARC Mate 120iD/12L

- Designed specifically for welding applications, this model features outstanding axis speeds and ultimate precision within its class. The highly versatile robot can weld large parts thanks to its very long horizontal stroke.

-

Arc Welding Robot ARC Mate 50iD

- The latest generation ARC Mate 50, this 6-axis standard version is a rugged all-rounder that will maintain high quality standards in harsh working environments.

-

CR-14iA/L

- CR-14iA/L is the perfect match between a small size and a heavy payload.

-

CR-15iA

- CR-15iA has just the right payload and reach for a wide-range of handling applications.

-

CR-35iB Collaborative Robot

- The CR-35iB is not only a FANUC but the world’s strongest collaborative robot with a lifting capacity of up to 50 kg. The load capacity combined with its extensive reach and safety certification makes it ideally suited to a wide range processes involving heavy lifting and positioning that was traditionally carried out by humans.

-

CR-4iA

- With six axis in my arm, and my maximum payload is 4kg. I handle lightweight tasks that are tedious, highly manual. My compact nature enables me to perform smaller jobs in areas with limited space requirements. It is possible for me to be wall- or invert-mounted, offering me a wider range of motion without interfering with the operator’s workspace.

-

CR-7iA and CR-7iA/L

- I’m small, flexible and can work right by your side. I take care of light (up to 7 kg) but tedious and repetitive, manual tasks that include different types of material handling, which would otherwise consume an immense amount of your time.

-

CRX-10iA Collaborative Robot

- The CRX-10iA is highly protected against dust or oil leakages common in industrial environments and fully complies with ISO 10218-1 safety standards. Because of its very low weight, the CRX can be easily installed in a broad range of applications such as automated guided vehicles (AGV).

-

CRX-10iA/L Collaborative Robot

- The CRX-10iA/L Collaborative Robot with a 10kg payload, 1,418mm reach and unique underflip motion renders it a perfect solution.

-

CRX-20iA/L Collaborative Robot

- The CRX-20iA/L Collaborative Robot, with a 20 kg payload, 1,418 mm reach and impressive underflip motion, is the perfect solution for manufacturers with little to no robotic experience. The CRX series offers an all-new FANUC programming interface with simple drag and drop functionality on a tablet teach pendant.

-

CRX-25iA Collaborative Robot

- The CRX-25iA Collaborative Robot is the perfect solution for manufacturers with little to no robotic experience as the CRX series offers a FANUC programming interface with simple drag and drop functionality on a tablet teach pendant.

-

CRX-5iA Collaborative Robot

- The CRX-5iA Collaborative Robot, with a 5 kg payload and 994 mm reach is the perfect solution for manufacturers with little to no robotic experience.

-

M-1000iA

- The M-1000iA is FANUC’s largest robot to feature a serial link mechanism, rather than the parallel link mechanism typical of most heavy payload robots. As a result, the M-1000iA gives a wider range of motion in both vertical and longitudinal directions.

-

M-10iD/10L

- The new long arm model of the M-10 series features an outstanding axes speed and ultimate precision within its class. Made specifically for narrow installations, this highly versatile robot can work on relative large parts thanks to its large horizontal stroke and can also be installed upside down or angle mounted.

-

M-10iD/12

- The new M-10iD/12 robot reaches the highest axis speed and precision in its class. Especially for narrow work spaces, or when being mounted upside down, this highly versatile robot gives a full working envelope, reach and stroke for higher production throughput.

-

M-10iD/12 Dustproof

- The new M-10iD/12 dustproof robot comes with IP67 motor covers perfect for applications in the forging, metal castings, ceramic industries, this highly versatile robot gives a full working envelope, reach and stroke for higher production throughput.

-

M-10iD/12 Food grade

- The M-10iD/12 food grade robot is designed for users in the food industry that need high-speed and high-payload robots.

-

M-10iD/16S

- Made specifically for compact work spaces, this highly versatile robot can also be used for top mount applications. Moreover, the enhanced hollow wrist design supports payloads up to 16 kg, which is a significant improvement compared to its predecessors and the best reference in its class.

-

M-10iD/8L

- Ideally suited for working in compact robotic cells, the slimline M-10iD/8L occupies a small footprint and can be installed upside down or angle mounted for even more flexibility. For easy and reliable routing of sensor or camera cables, air pipes and other utilities, services are routed through the robot’s hollow arm, wrist and body.

-

M-2000iA/1200

- The M-2000iA/1200 is a powerful heavy-duty robot still has what it takes to satisfy all but the most very demanding of high-payload material handling applications.

-

M-2000iA/1700L

- With its 1.7 t payload capacity and 6.2 m stroke, it provides maximum flexibility on operations involving large and heavy objects. Capable of effortlessly lifting and positioning an entire car body within its generous work envelope, this robot has been designed to improve workflow, increase efficiency and to reduce your costs.

-

M-2000iA/2300

- With its enormous 2.3 t payload, the M-2000iA/2300 is the biggest lifter in the range. Ideally suited to heavyweight material handling applications that require an even stronger wrist, this machine will easily lift and position an entire car or load bulky set castings onto machine fixtures.

-

M-2000iA/900L

- Boasting an outstanding vertical lifting stroke and a payload capacity of 900 kg, this heavy-duty long-arm version makes light of even heavy load applications.

-

M-20iB/25

- Combining a lightweight hollow upper arm and wrist with advanced servo technology, the M-20iB series has been designed to achieve faster cycles and increased throughput on a range of applications. Models come fully encapsulated to IP67 standard, making them ideally suited to wet, dirty and harsh processes such as auto deburring.

-

M-20iB/25C

- The FANUC M-20iB/25C comes in special white paint indicating its resistance against cleaning agents and used in daily wash down operations typical for cleanroom environments such as 2nd-Food areas or the medial, optical, pharmaceutical or electronics industry.

-

M-20iB/35S

- Equipped with a lightweight upper arm and inline wrist, and weighing just 205 kg, the M-20iB/35S delivers high inertia and lifts a full 35 kg. This, combined with its compact design and narrow arm, makes it ideally suited to numerous highpayload machine tending and loading applications in a small footprint.

-

M-20iD/12L

- Designed specifically for handling applications, this model features outstanding axis speeds and ultimate precision within its class. The highly versatile robot can handle large parts thanks to its very long horizontal stroke. To further maximise flexibility and open up a new range of application possibilities, it can also carry additional tools weighing up to 12 kg.

-

M-20iD/25

- Offering high performance in a small footprint, the FANUC M-20iD/25 is ideally suited to loading and unloading machines as well as parts handling and positioning in crowded factory environments. For best access, it features a compact arm and wrist and, thanks to its new improved design and drive train, offers significantly higher axis speeds and motion performance.

-

M-20iD/25 Food grade

- Offering high performance in a small footprint, the FANUC M-20iD/25 food grade robot is designed for users in the food industry that need high-speed and high-payload robots. It features food grade oil on all axes, stainless-steel wrist flange, motor covers, corrosion-resistant fasteners, white epoxy paint, and protection against severe dust and liquid combined with higher axis speeds and motion performance.…

-

M-20iD/35

- With a payload of 35 kg this robot is designed for material handling of large parts. Equipped with outstanding axis speeds and ultimate precision within its class this robot is suitable for a wide range of applications.

-

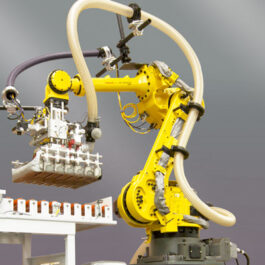

M-410iB/140H

- Designed specifically for the job by the company that built the world's first dedicated palletising robot, the M-410 series increases throughput on palletising and handling applications. Extremely fast, versatile and offering the best repeatability in the range, this 5-axis robot will cope with any number of varied palletising applications.

-

M-410iB/700

- Boasting the best payload capacity of the range, this robot will lift up to 700 kg and is equipped with a hollow wrist to minimise the risk of cable snagging and reduce maintenance.

-

M-410iC/110

- Built on the basis of the FANUC M-410 model series, this 4-axes robot stands out based on its slim design and optimised kinematics. These features allow it to perform palletising tasks at a high speed (throughput of 2200 cycles per hour) while making the most efficient use of the available workspace.

-

M-410iC/185

- Designed specifically for the job by the company that built the world's first dedicated palletising robot, the M-410 series increases throughput on palletising and handling applications. This compact 4-axis model is your choice for high speed pallatising, assembly, machining and parts transfer applications.

-

M-410iC/315

- Designed specifically for the job by the company that built the world's first dedicated palletising robot, the M-410 series increases throughput on palletising and handling applications. This 4-axis compact palletising model has been specifically engineered for precision and high-speed handling of payloads up to 315 kg.

-

M-410iC/500

- The M-410iC/500 palletising robot replaces the M-410iC/450. Stronger and faster than the 450, the M-410iC/500 improves throughput and will lift 500 kg. Designed specifically for the job by the company that built the world's first dedicated palletising robot, the M-410 series is the solution for palletising and handling applications.

-

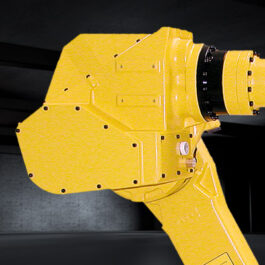

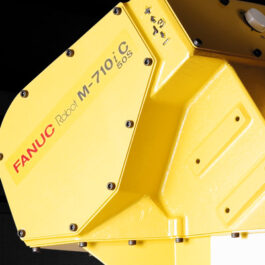

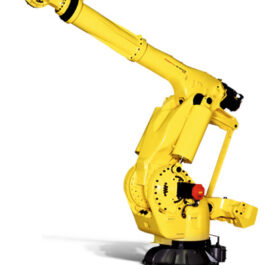

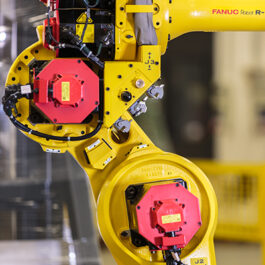

M-710iC/12L

- the M-710iC/12L is a small to medium payload 6-axis model that is ideal for all applications to handle medium payloads for up to 12 kg.

-

M-710iC/20L

- The M-710iC/20L will handle lighter payloads within a large operating envelope. It is especially popular for applications such as machine tending, grinding, polishing, deburring, water jet cutting and washing.

-

M-710iC/20M

- The M-710iC/20M industrial robot has been specifically designed to work in small spaces and is particularly suitable for operations involving arc welding, material handling and sealant application.

-

M-710iC/45M

- Combining speed with a wide work envelope, this model is ideally suited to high-speed transfer operations when fitted with a drive enhancement unit. Its compact design and slim wrist make it a great choice for handling operations where space is at a premium.

-

M-710iC/50

- This innovative series of lightweight robots features a slim wrist, rigid arm and small footprint. High axis speeds combined with huge 6-axis versatility make it the perfect choice for handling awkward payloads.

-

M-710iC/50E

- This 6-axis medium payload model is the perfect choice for the versatile handling of large and heavier workpieces and a popular robot for machine tending, grinding, polishing, deburring, water jet cutting and washing applications.

-

M-710iC/50H

- This innovative series of lightweight robots features a slim wrist, rigid arm and small footprint. High axis speeds make it extremely fast, while the 5-axis design makes it ideal for packing and palletising applications.

-

M-710iC/50S

- This innovative series of lightweight robots features a slim wrist, rigid arm and small footprint. High axis speeds make it extremely fast.

-

M-710iC/50T

- This innovative series of lightweight robots features a slim wrist, rigid arm and small footprint. High axis speeds make it extremely fast. Capable of handling 50 kg, this top mount version is the lightest model in the range.

-

M-710iC/70

- Offering best payload and inertia in its category, this powerful 6-axis model is suitable for various applications and combines a 70 kg payload with extremely high axis speeds.

-

M-710iC/70T

- Offering extremely good repeatability, this top mount version is the lightest in the range. Capable of handling 70 kg, its versatile mounting options save you floor space.

-

M-800iA/60

- The unique combination of characteristics allows manufacturers to significantly improve the quality of laser cutting, welding, or in general processes with a very high demand on accuracy. Especially for the automotive and aerospace industries, where requirements for accuracy have been steadily on the rise, the M-800iA/60 offers outstanding precision without slowing down the production process.

-

M-900iB/280

- The M-900iB/280 has been tested to ISO 9283 rigidity standards and exhibits a very high level of static compliance. This makes it ideally suited to operations where pressure is applied to the tool and accuracy essential.

-

M-900iB/280L

- Already highly versatile thanks to its 6 axes, its supporting parallel link arm makes it even more suited to accurate handling of heavy workpieces, palletising in complete layers and heavy duty spot welding.

-

M-900iB/330L

- This long arm model comes with a compact mechanical construction ensuring an optimal weight-payload ratio. The large work envelope with a horizontal reach of 3203 mm and a vertical reach of 3539 mm makes it an ideal solution for heavy spot welding and material handling application like palletising.

-

M-900iB/360E

- This model is ideally suited to the heavier payloads involved in assembly, parts transfer and loading applications. Floor and ceiling mounting options make it extremely flexible, with its 6 axes providing the dexterity required for fast accurate handling.

-

M-900iB/400L

- Thanks to stable floor mounting and a huge lifting capacity this model is ideally suited to applications involving heavy payloads. Additional flexibility is provided by its extended reach and 6 axes. This makes it a great solution for processes requiring heavy-weight handling within a wider work envelope.

-

M-900iB/700

- This 6 axis model is a big lifter that also benefits from a generous work envelope. Capable of handing up to 700 kg, it is perfectly cut out for the kind of heavy loading, unloading and tending applications found in the metal, automotive and construction industries.

-

M-900iB/700E

- This 6 axis model is the enhanced wrist version of M-900iB/700, capable of handing up to 700 kg, with increased load moment. It is the perfect choice for heavy lifting, loading, unloading and tending applications typical of the metal, automotive and construction industries.

-

P-250iB/15

- This paint robot is the industry's best solution for large and mid-size painting jobs. Suitable for a wide range of painting and coating applications, it has a large handling capacity and generous work envelope.

-

P-350iA/45

- Designed to be flexible and to fulfil a wide range of applications, the P-350iA is a large payload paint robot with a 45 kg wrist capacity. It is completely airtight thanks to PTFE or EPDM gaskets on all covers.

-

P-40iA

- The P-40iA robot is extremely flexible and easily adapts to small lot sizes, new styles and other modifications, providing customers an affordable and versatile solution for robotic painting applications.

-

P-50iB/10L

- Ultra compact, this high reach paint model provides a reliable and precise painting and coating solution for a huge range of industries. An affordable choice, it benefits from a long reach and internal cabling.

-

Paint Mate 200iA/5L

- The long arm Paint Mate 200iA/5L is a versatile, compact paint robot with an increased maximum reach and 5 kg payload capacity. Ideal for painting applications, assembly and handling operations requiring increased reach even in hazardous environments.

-

R-1000iA/100F

- This 6 axis robot has the inherent flexibility to complete any number of challenging jobs. Very fast and capable of realising excellent cycle times, it is particularly suited to a wide range of high-speed spot welding applications. Compact and lightweight, it also saves you space.

-

R-1000iA/120F-7B

- Based on an added seventh axis in its second arm, the R-1000iA/120F-7B gains more agility, making it ideal for material handling and spot welding. Nevertheless, its’ compact design enables it to fully operate within small work cells, reaching the same cycle times as the six-axis.

-

R-1000iA/130F

- Suitable for a diversity of industries and applications, the new top model of the R-1000iA series comes with a payload of 130 kg. Despite the high payload, the R-1000iA/130F is still able to reach a high level of compactness that allows it to work in small cells - which comes at no cost to its productivity or performance levels.

-

R-1000iA/80F

- This robot is a versatile high-speed performer, capable of fast acceleration and improved cycle times on a range of operations including welding, handling and palletising. Its 6 axes provide huge flexibility across a range of applications with standard wrist protection making it capable of working in wet and dusty environments.

-

R-1000iA/80H

- With its slim design and small footprint, this model saves precious floor space and is ideally suited to compact cells. And thanks to its speed and 5th axis, it makes a great choice on palletising applications requiring high rates of throughput and maximum reliability.

-

R-2000iC/100P

- The R-2000iC/100P guarantees top productivity for press to press transfer applications in Automotive and Automotive Components industries. Fast and versatile, it has been designed to reduce cycle times on a range of operations.

-

R-2000iC/125L

- This model adds an extra big reach to the high performance capabilities and payload capacities offered by this world-beating series of robots.

-

R-2000iC/165F

- Equipped with a thin wrist and capable of delivering excellent cycle times, it makes a nimble spot welding robot on automotive and similar applications. It has also been designed to maximise use of space and enable it to work in close proximity to other robots.

-

R-2000iC/165R

- This rack-mounted model is ideal for increasing your productivity on shelf installations such as press, CNC machining and other machine tending applications.

-

R-2000iC/190S

- Although the use of robots for applications like milling is not new, most solutions to date centre on workpiece materials such as plastic and resin. However, with the R-2000iC/190S one can mill more challenging materials that include aluminium and wood with good levels of accuracy.

-

R-2000iC/210F

- With numerous mounting options available to make best use of space and create an optimal work envelope, it makes an excellent spot welding robot. Additional options make it suitable for food processing applications or wet environments.

-

R-2000iC/210L

- The R-2000iC/210L is ideally suited to automotive applications such as spot welding. Its relatively small footprint means it easily fits into crowded factory environments.

-

R-2000iC/210R

- This rack-mounted model saves space yet offers enormous flexibility thanks to its huge 3095 mm work envelope. Offering high performance and excellent payload capacities, it makes the perfect solution for a multitude of high-payload applications.

-

R-2000iC/210WE

- For a variety of washing applications, this strong and robust robot model will be able to withstand the harsh operating (e.g. washing) environments. Thanks to its mechanical design and IP67 protection as a standard, it is resistant to wet, dusty or dirty tasks, while being capable of lifting heavy weights up to 210kg.

-

R-2000iC/220U

- Being part of the most powerful robot series, the R-2000iC/220U is made to fit a variety of workspaces, while handling high payloads at a high level of precision. This mobile industrial robot model can be adapted to limited space cells by mounting it to the ceiling.

-

R-2000iC/240F

- With numerous mounting options available to make best use of space and create an optimal work envelope. it makes an excellent spot welding robot. Additional options make it suitable for food processing applications or wet environments.

-

R-2000iC/270F

- Sitting within a relatively small footprint, its design makes best use of space in crowded factory environments. On spot welding applications, its strength, compactness and speed come to the fore.

-

R-2000iC/270R

- The latest edition to the R-2000iC series, completes the portfolio of rack-mounted robots up to high payload classes. With an enforced J3 arm, this model is able to carry payloads up to 270 kg.

-

R-2000iD/100FH

- Featuring 100kg payload, this model is ideally suited to any number of heavy handling jobs on almost any application. Its hollow arm design allows completely internal cable routing by easy accessibility of the integrated process cables for an independent exchange due to wide open maintenance slots.

-

R-2000iD/165FH

- This hollow arm robot model with a payload of 165 kg is ideally suited for all applications which require process cables, such as spot welding or material handling applications.

-

R-2000iD/210FH

- Featuring a huge 210 kg payload, this model is ideally suited to any number of heavy handling jobs on almost any application.

-

SCARA Robot SR-12iA

- Small, lightweight and internally routed cables/pipes give the robot a clear and clean look, which minimize Interference contour and simplify the integration of the FANUC SR-12iA into any assembly or packaging line.

-

SCARA Robot SR-20iA

- Internally routed cables/pipes give the robot a clear and clean look. which minimise interference contour and simplify the integration of the FANUC SR-20iA into any assembly or packaging line.

-

SCARA Robot SR-3iA

- With its 3 kg payload, 400 mm horizontal and 200 mm vertical reach, the FANUC SR-3iA is ideally suited to smaller-scale assembly, pick and place, inspection and packaging applications.

-

SCARA Robot SR-3iA/C

- The SR-3iA/C features a white epoxy coating, food grease and complies ISO Class 5, making it perfectly suitable for Cleanroom and Food applications.

-

SCARA Robot SR-6iA

- Sitting in a small footprint, the SR-6iA offers speed and precision within a 360° envelope. Its lightweight pedestal-design and integrated services minimise the risk of interference with peripheral devices.

-

SCARA Robot SR-6iA/C

- The FANUC SR-6iA/C makes a great choice for handling, picking and placing, and packaging applications requiring a payload capacity up to 6 kg.

-

SR-3iA/U

- The ceiling-mounted, fast and precise FANUC SR-3iA/U robot eliminates the so-called ‘dead zone’ that conventional SCARA robots typically suffer.