Fanuc

-

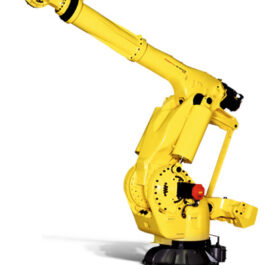

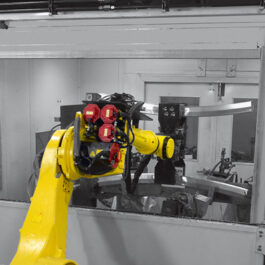

M-800iA/60

- The unique combination of characteristics allows manufacturers to significantly improve the quality of laser cutting, welding, or in general processes with a very high demand on accuracy. Especially for the automotive and aerospace industries, where requirements for accuracy have been steadily on the rise, the M-800iA/60 offers outstanding precision without slowing down the production process.

-

M-900iB/280

- The M-900iB/280 has been tested to ISO 9283 rigidity standards and exhibits a very high level of static compliance. This makes it ideally suited to operations where pressure is applied to the tool and accuracy essential.

-

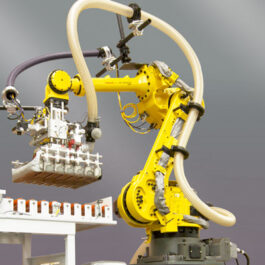

M-900iB/280L

- Already highly versatile thanks to its 6 axes, its supporting parallel link arm makes it even more suited to accurate handling of heavy workpieces, palletising in complete layers and heavy duty spot welding.

-

M-900iB/330L

- This long arm model comes with a compact mechanical construction ensuring an optimal weight-payload ratio. The large work envelope with a horizontal reach of 3203 mm and a vertical reach of 3539 mm makes it an ideal solution for heavy spot welding and material handling application like palletising.

-

M-900iB/360E

- This model is ideally suited to the heavier payloads involved in assembly, parts transfer and loading applications. Floor and ceiling mounting options make it extremely flexible, with its 6 axes providing the dexterity required for fast accurate handling.

-

M-900iB/400L

- Thanks to stable floor mounting and a huge lifting capacity this model is ideally suited to applications involving heavy payloads. Additional flexibility is provided by its extended reach and 6 axes. This makes it a great solution for processes requiring heavy-weight handling within a wider work envelope.

-

M-900iB/700

- This 6 axis model is a big lifter that also benefits from a generous work envelope. Capable of handing up to 700 kg, it is perfectly cut out for the kind of heavy loading, unloading and tending applications found in the metal, automotive and construction industries.

-

M-900iB/700E

- This 6 axis model is the enhanced wrist version of M-900iB/700, capable of handing up to 700 kg, with increased load moment. It is the perfect choice for heavy lifting, loading, unloading and tending applications typical of the metal, automotive and construction industries.

-

P-250iB/15

- This paint robot is the industry's best solution for large and mid-size painting jobs. Suitable for a wide range of painting and coating applications, it has a large handling capacity and generous work envelope.

-

P-350iA/45

- Designed to be flexible and to fulfil a wide range of applications, the P-350iA is a large payload paint robot with a 45 kg wrist capacity. It is completely airtight thanks to PTFE or EPDM gaskets on all covers.

-

P-40iA

- The P-40iA robot is extremely flexible and easily adapts to small lot sizes, new styles and other modifications, providing customers an affordable and versatile solution for robotic painting applications.

-

P-50iB/10L

- Ultra compact, this high reach paint model provides a reliable and precise painting and coating solution for a huge range of industries. An affordable choice, it benefits from a long reach and internal cabling.

-

Paint Mate 200iA/5L

- The long arm Paint Mate 200iA/5L is a versatile, compact paint robot with an increased maximum reach and 5 kg payload capacity. Ideal for painting applications, assembly and handling operations requiring increased reach even in hazardous environments.

-

R-1000iA/100F

- This 6 axis robot has the inherent flexibility to complete any number of challenging jobs. Very fast and capable of realising excellent cycle times, it is particularly suited to a wide range of high-speed spot welding applications. Compact and lightweight, it also saves you space.

-

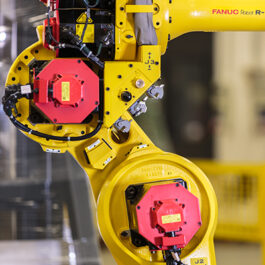

R-1000iA/120F-7B

- Based on an added seventh axis in its second arm, the R-1000iA/120F-7B gains more agility, making it ideal for material handling and spot welding. Nevertheless, its’ compact design enables it to fully operate within small work cells, reaching the same cycle times as the six-axis.

-

R-1000iA/130F

- Suitable for a diversity of industries and applications, the new top model of the R-1000iA series comes with a payload of 130 kg. Despite the high payload, the R-1000iA/130F is still able to reach a high level of compactness that allows it to work in small cells - which comes at no cost to its productivity or performance levels.

-

R-1000iA/80F

- This robot is a versatile high-speed performer, capable of fast acceleration and improved cycle times on a range of operations including welding, handling and palletising. Its 6 axes provide huge flexibility across a range of applications with standard wrist protection making it capable of working in wet and dusty environments.

-

R-1000iA/80H

- With its slim design and small footprint, this model saves precious floor space and is ideally suited to compact cells. And thanks to its speed and 5th axis, it makes a great choice on palletising applications requiring high rates of throughput and maximum reliability.

-

R-2000iC/100P

- The R-2000iC/100P guarantees top productivity for press to press transfer applications in Automotive and Automotive Components industries. Fast and versatile, it has been designed to reduce cycle times on a range of operations.

-

R-2000iC/125L

- This model adds an extra big reach to the high performance capabilities and payload capacities offered by this world-beating series of robots.

-

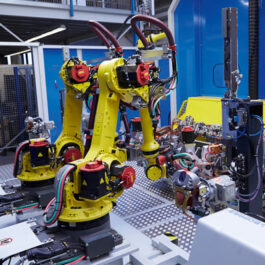

R-2000iC/165F

- Equipped with a thin wrist and capable of delivering excellent cycle times, it makes a nimble spot welding robot on automotive and similar applications. It has also been designed to maximise use of space and enable it to work in close proximity to other robots.

-

R-2000iC/165R

- This rack-mounted model is ideal for increasing your productivity on shelf installations such as press, CNC machining and other machine tending applications.

-

R-2000iC/190S

- Although the use of robots for applications like milling is not new, most solutions to date centre on workpiece materials such as plastic and resin. However, with the R-2000iC/190S one can mill more challenging materials that include aluminium and wood with good levels of accuracy.

-

R-2000iC/210F

- With numerous mounting options available to make best use of space and create an optimal work envelope, it makes an excellent spot welding robot. Additional options make it suitable for food processing applications or wet environments.

End of content

No more pages to load