Fanuc

-

R-2000iC/210L

- The R-2000iC/210L is ideally suited to automotive applications such as spot welding. Its relatively small footprint means it easily fits into crowded factory environments.

-

R-2000iC/210R

- This rack-mounted model saves space yet offers enormous flexibility thanks to its huge 3095 mm work envelope. Offering high performance and excellent payload capacities, it makes the perfect solution for a multitude of high-payload applications.

-

R-2000iC/210WE

- For a variety of washing applications, this strong and robust robot model will be able to withstand the harsh operating (e.g. washing) environments. Thanks to its mechanical design and IP67 protection as a standard, it is resistant to wet, dusty or dirty tasks, while being capable of lifting heavy weights up to 210kg.

-

R-2000iC/220U

- Being part of the most powerful robot series, the R-2000iC/220U is made to fit a variety of workspaces, while handling high payloads at a high level of precision. This mobile industrial robot model can be adapted to limited space cells by mounting it to the ceiling.

-

R-2000iC/240F

- With numerous mounting options available to make best use of space and create an optimal work envelope. it makes an excellent spot welding robot. Additional options make it suitable for food processing applications or wet environments.

-

R-2000iC/270F

- Sitting within a relatively small footprint, its design makes best use of space in crowded factory environments. On spot welding applications, its strength, compactness and speed come to the fore.

-

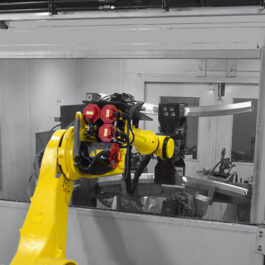

R-2000iC/270R

- The latest edition to the R-2000iC series, completes the portfolio of rack-mounted robots up to high payload classes. With an enforced J3 arm, this model is able to carry payloads up to 270 kg.

-

R-2000iD/100FH

- Featuring 100kg payload, this model is ideally suited to any number of heavy handling jobs on almost any application. Its hollow arm design allows completely internal cable routing by easy accessibility of the integrated process cables for an independent exchange due to wide open maintenance slots.

-

R-2000iD/165FH

- This hollow arm robot model with a payload of 165 kg is ideally suited for all applications which require process cables, such as spot welding or material handling applications.

-

R-2000iD/210FH

- Featuring a huge 210 kg payload, this model is ideally suited to any number of heavy handling jobs on almost any application.

-

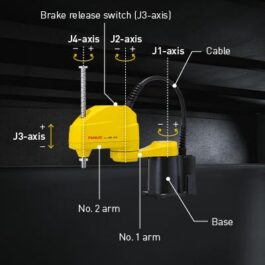

SCARA Robot SR-12iA

- Small, lightweight and internally routed cables/pipes give the robot a clear and clean look, which minimize Interference contour and simplify the integration of the FANUC SR-12iA into any assembly or packaging line.

-

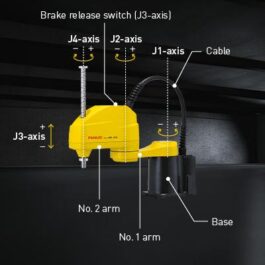

SCARA Robot SR-20iA

- Internally routed cables/pipes give the robot a clear and clean look. which minimise interference contour and simplify the integration of the FANUC SR-20iA into any assembly or packaging line.

-

SCARA Robot SR-3iA

- With its 3 kg payload, 400 mm horizontal and 200 mm vertical reach, the FANUC SR-3iA is ideally suited to smaller-scale assembly, pick and place, inspection and packaging applications.

-

SCARA Robot SR-3iA/C

- The SR-3iA/C features a white epoxy coating, food grease and complies ISO Class 5, making it perfectly suitable for Cleanroom and Food applications.

-

SCARA Robot SR-6iA

- Sitting in a small footprint, the SR-6iA offers speed and precision within a 360° envelope. Its lightweight pedestal-design and integrated services minimise the risk of interference with peripheral devices.

-

SCARA Robot SR-6iA/C

- The FANUC SR-6iA/C makes a great choice for handling, picking and placing, and packaging applications requiring a payload capacity up to 6 kg.

-

SR-3iA/U

- The ceiling-mounted, fast and precise FANUC SR-3iA/U robot eliminates the so-called ‘dead zone’ that conventional SCARA robots typically suffer.

End of content

No more pages to load