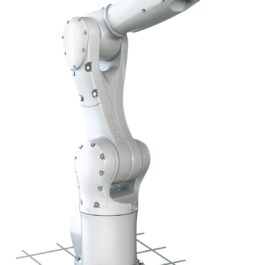

Description

- The IRB 7600-500/2.55 is ideal for heavy applications, regardless of industry.

- Typical uses include the handling of heavy fixtures and parts, turning car bodies, lifting engines, in foundries or forges, loading and unloading of machine cells.

- It can also be used to lift large, heavy pallet layers.

- With all these applications the moment of inertia is very high which allows the IRB 7600 to handle heavy and wide parts.

- A major challenge with robots handling payloads of up to 500 kg is ensuring the safety for personnel and protecting expensive equipment.

- From the unlikely event of an accident.

- As a result, ABB has developed SafeMove2, a safety certified robot supervision solution that allows lean and flexible robotic system.

Features:

- It includes a host of cutting-edge safety functions, including safe speed limits, safe standstill monitoring.

- Safe axis ranges and position and orientation supervision.

- All combined, collaboration between robots and factory workers or factory floor space savings are possible at a low total cost of investment.

- The IRB 7600-500/2.55 is avalible with LeanID Dress Pack.

- An option that improves the possibility with many complex wrist movements.

- And where the need for flexibility in changing products is high.

- Reliable – High production up time

- Security – A safe investment

- Fast – Short cycle times

- Accurate – Consistent parts quality

- Strong – Maximized utilization

- Robust – Harsh production environment

- Versatile – Flexible integration and production

- A major challenge with robots handling payloads of up to 500 kg is ensuring the safety for personnel and protecting expensive equipment.

- As a result, ABB has developed SafeMove2, a safety certified robot supervision solution that allows lean and flexible robotic systems.

- IRB 7600-500/2.55 includes a host of cutting-edge safety functions, including safe speed limits, safe standstill monitoring, safe axis ranges and position and orientation supervision.

Reviews

There are no reviews yet.