Description

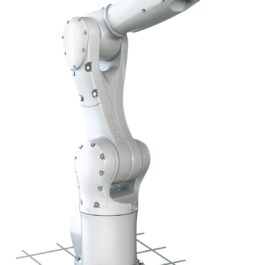

- In designing the ABB IRB 8700, ABB focused on delivering a reliable robot with a low total cost of ownership.

- Through a combination of robust design elements, including simpler parts configurations where possible.

- ABB Robotics applied decades of engineering experience to combine the high performance customers require with low overall maintenance needs.

- In addition, the IRB 8700 delivers 25% faster speeds than any other robot in this class size.

- High payloads up to 1000 kg with the wrist down

- 25% faster speeds than other robots in this size class

- Highly reliable with simplified design and Foundry Plus 2 protection standard

- Built around LeanID for reduced wear on dress packs and ease of simulation

- Built using non-hazardous materials

- With a straightforward and uncomplicated design that uses world-class components.

- LeanID for the best cost-to-endurance ratio in a dress pack, and ABB’s Foundry Plus 2 as standard protection.

- The ABB IRB 8700 will run with very high uptime—a key feature in production lines that operate around the clock.

- The IRB 8700 has only one motor and one gear per robot axis, while most other robots in this size class use dual motors and/or gears.

- In addition, there are no gas springs that can leak and cause safety problems.

- Only a reliable counterweight and mechanical springs for counter balancing.

- Together these design elements mean fewer components to fail while delivering shorter cycle times and higher accuracy.

- With LeanID, ABB IRB 8700 has developed a concept that is less expensive than completely integrated dress packs.

- But still delivers most of the benefits for a fraction of the cost.

- LeanID results in a robot that is easy to simulate in offline programming, has a long dress pack lifetime.

- Supports flexible production with a large working range, and can easily enter tight spaces.

Reviews

There are no reviews yet.