Description

Collaborative Robotics in Industry Specialization

What you’ll learn

- Collaborative Robotics in Industry, Mechatronics systems and their Utility Interfacing of Sensors and Transducers.

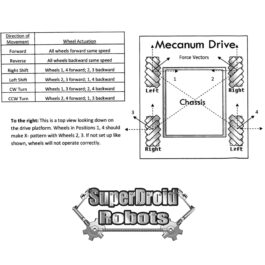

- Interfacing of Drive systems with Electronics control system.

Advance your subject-matter expertise

- Learn in-demand skills from university and industry experts

- Master a subject or tool with hands-on projects

- Develop a deep understanding of key concepts

- Earn a career certificate from L&T Edu Tech

Earn a career certificate

- Add this credential to your LinkedIn profile, resume, or CV.

- Share it on social media and in your performance review.

Specialization – 3 course series

- Collaborative Robotics in Industry merges traditional manufacturing with cutting-edge robotics.

- Equipping learners with skills to navigate modern manufacturing.

- Foundational Industrial Manufacturing knowledge highlights robotics’ role in enhancing efficiency and precision.

- Introductory Mechatronics integrates engineering principles for robotic system development.

- Understanding Introductory Electronics aids in comprehending digital control circuitry and sensor technologies.

- Applied Physics principles furnish analytical tools for robotic system design.

- Graduates excel in Robotic Manipulator and Gripper Design.

- Integrating Mechanical Components with Digital Control Circuitry for optimized performance.

- Sensor & Transducer Technology mastery enables real-time monitoring and control, enhancing productivity.

- Drive Systems expertise ensures adaptability to diverse manufacturing environments.

- Troubleshooting in Mechatronic Systems and System Design using MATLAB-Simulink enables efficient issue resolution.

- Robot Programming skills empower precise and efficient control.

- Robotic Vision Systems and Machine Vision augment automation and quality control.

- Integration of IIoT technologies drives efficiency in collaborative robotic systems.

- Graduates find career opportunities as Automation Engineers and Robotic Designers, shaping the future of manufacturing with innovation and efficiency.

- For heavy load handling purpose utilize the electro-hydraulic systems.

- Prepare a blue print to carry out this project comprising all the essentials like appropriate sensors, drive systems, electronic circuitry and fluid circuitry.

- Interface the developed robot with a control system.

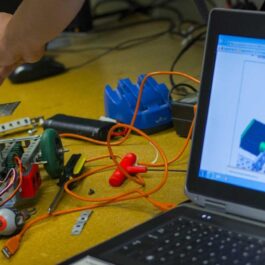

- Find out an appropriate ICs and essential electronic circuit elements.

- Choose prototyping platforms either Arduino or Raspberry Pi.

- Apply the IIoT concepts.

- Choose a relevant gate way and connectivity to monitor its functioning and enhance the productivity.

Reviews

There are no reviews yet.