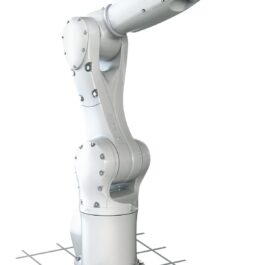

Industrial Robots

-

KR 6 R900 EX

- KR 6 R900 EX gives top performance in practice at a reasonable price.

-

KR 6 R900 HM-SC

- KR 6 R900 HM-SC gives top performance in practice at a reasonable price.

-

KR 6 R900 WP

- KR 6 R900 WP gives top performance in practice at a reasonable price. You can depend on the robot carrying out its work reliably in a wide variety of applications and environments.

-

KR 6 R900-2

- KR 6 R900-2 gives top performance in practice at a reasonable price. You can depend on the robot carrying out its work reliably in a wide variety of applications and environments.

-

KR 6 R900-2 HO

- KR 6 R900-2 HO gives top performance in practice at a reasonable price. You can depend on the robot carrying out its work reliably in a wide variety of applications and environments.

-

KR 600 R2830

- KUKA KR 600 R2830 offers a broad portfolio for the food sector. In addition to the portfolio, KUKA also offers hygienic machine robots

-

KR 600 R2830 F

- KUKA KR 600 R2830 F offers a broad portfolio for the food sector. In addition to the portfolio, KUKA also offers hygienic machine robots

-

KR 640 R2800-2

- KUKA KR640 R2800-2 offers a broad portfolio for the food sector. In addition to the portfolio, KUKA also offers hygienic machine robots

-

KR 640 R2800-2 HI

- KUKA KR640 R2800-2 HI offers a broad portfolio for the food sector. In addition to the portfolio, KUKA also offers hygienic machine robots

-

KR 70 R2100

- KUKA KR 70 R2100 offers a broad portfolio for the food sector. In addition to the portfolio, KUKA also offers hygienic machine robots

-

KR 70 R2100 CR lite

- KUKA KR 70 R2100 CR lite offers a broad portfolio for the food sector. In addition to the portfolio, KUKA also offers hygienic machine robots

-

KR 70 R2100 F

- KUKA KR 70 R2100 F offers a broad portfolio for the food sector. In addition to the portfolio, KUKA also offers hygienic machine robots

-

KR 70 R2100 HO

- KUKA KR 70 R2100 HO offers a broad portfolio for the food sector. In addition to the portfolio, KUKA also offers hygienic machine robots

-

KR 700 PA ROBOT

- The KR 700 PA ROBOT is your ideal palletizer for heavier payloads.

-

KR 8 R1420 arc HW

- KUKA 8 R1420 arc HW offers a broad portfolio for the food sector. In addition to the HO portfolio, KUKA also offers hygienic machine robots

-

KR 8 R1440-2 arc HW

- KUKA KR 8 R1440-2 arc HW offers a broad portfolio for the food sector. In addition to the HO portfolio, KUKA also offers hygienic machine robots

-

KR 8 R1620 arc HW

- KUKA KR 8 R1620-2 arc HW E offers a broad portfolio for the food sector. In addition to the HO portfolio, KUKA also offers hygienic machine robots

-

KR 8 R1640-2

- KR 8 R1640-2 gives top performance in practice at a reasonable price.

-

KR 8 R1640-2

- KUKA KR 8 R1640-2 offers a broad portfolio for the food sector. In addition to the HO portfolio, KUKA also offers hygienic machine robots (HM) and hygienic delta robots.

-

KR 8 R1640-2 arc HW

- KR 8 R1640-2 arc HW gives top performance in practice at a reasonable price.

-

KR 8 R1640-2 arc HW

- KUKA KR 8 R1640-2 arc HW offers a broad portfolio for the food sector. In addition to the HO portfolio, KUKA also offers hygienic machine robots

-

KR 8 R2010-2

- KUKA KR 8 R2010-2 offers a broad portfolio for the food sector. In addition to the HO portfolio, KUKA also offers hygienic machine robots

-

KR 800 R2800-2

- KUKA KR 800 R2800-2 offers a broad portfolio for the food sector. In addition to the portfolio, KUKA also offers hygienic machine robots

-

KUKA DELTA ROBOT

- Basically High-speed KUKA DELTA ROBOT in the hygienic machine variant for handling and picking of small parts.

End of content

No more pages to load