Industrial Robots

-

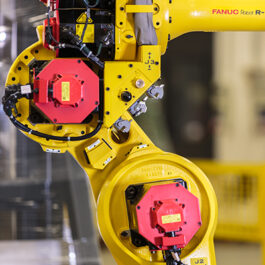

R-1000iA/100F

- This 6 axis robot has the inherent flexibility to complete any number of challenging jobs. Very fast and capable of realising excellent cycle times, it is particularly suited to a wide range of high-speed spot welding applications. Compact and lightweight, it also saves you space.

-

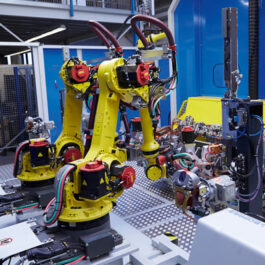

R-1000iA/120F-7B

- Based on an added seventh axis in its second arm, the R-1000iA/120F-7B gains more agility, making it ideal for material handling and spot welding. Nevertheless, its’ compact design enables it to fully operate within small work cells, reaching the same cycle times as the six-axis.

-

R-1000iA/130F

- Suitable for a diversity of industries and applications, the new top model of the R-1000iA series comes with a payload of 130 kg. Despite the high payload, the R-1000iA/130F is still able to reach a high level of compactness that allows it to work in small cells - which comes at no cost to its productivity or performance levels.

-

R-1000iA/80F

- This robot is a versatile high-speed performer, capable of fast acceleration and improved cycle times on a range of operations including welding, handling and palletising. Its 6 axes provide huge flexibility across a range of applications with standard wrist protection making it capable of working in wet and dusty environments.

-

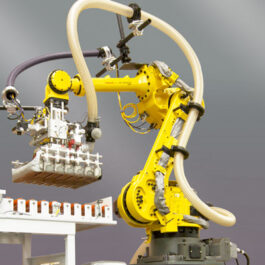

R-1000iA/80H

- With its slim design and small footprint, this model saves precious floor space and is ideally suited to compact cells. And thanks to its speed and 5th axis, it makes a great choice on palletising applications requiring high rates of throughput and maximum reliability.

-

R-2000iC/100P

- The R-2000iC/100P guarantees top productivity for press to press transfer applications in Automotive and Automotive Components industries. Fast and versatile, it has been designed to reduce cycle times on a range of operations.

-

R-2000iC/125L

- This model adds an extra big reach to the high performance capabilities and payload capacities offered by this world-beating series of robots.

-

R-2000iC/165F

- Equipped with a thin wrist and capable of delivering excellent cycle times, it makes a nimble spot welding robot on automotive and similar applications. It has also been designed to maximise use of space and enable it to work in close proximity to other robots.

-

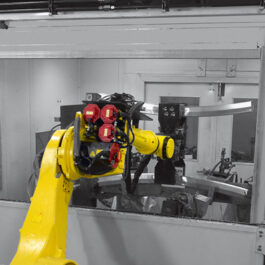

R-2000iC/165R

- This rack-mounted model is ideal for increasing your productivity on shelf installations such as press, CNC machining and other machine tending applications.

-

R-2000iC/190S

- Although the use of robots for applications like milling is not new, most solutions to date centre on workpiece materials such as plastic and resin. However, with the R-2000iC/190S one can mill more challenging materials that include aluminium and wood with good levels of accuracy.

-

R-2000iC/210F

- With numerous mounting options available to make best use of space and create an optimal work envelope, it makes an excellent spot welding robot. Additional options make it suitable for food processing applications or wet environments.

-

R-2000iC/210L

- The R-2000iC/210L is ideally suited to automotive applications such as spot welding. Its relatively small footprint means it easily fits into crowded factory environments.

End of content

No more pages to load